Home » Flow Meter » Ultrasonic Flow Meter » Flowmeter Water Wall Mounted Clamp On Ultrasonic Flow Meter Digital Water

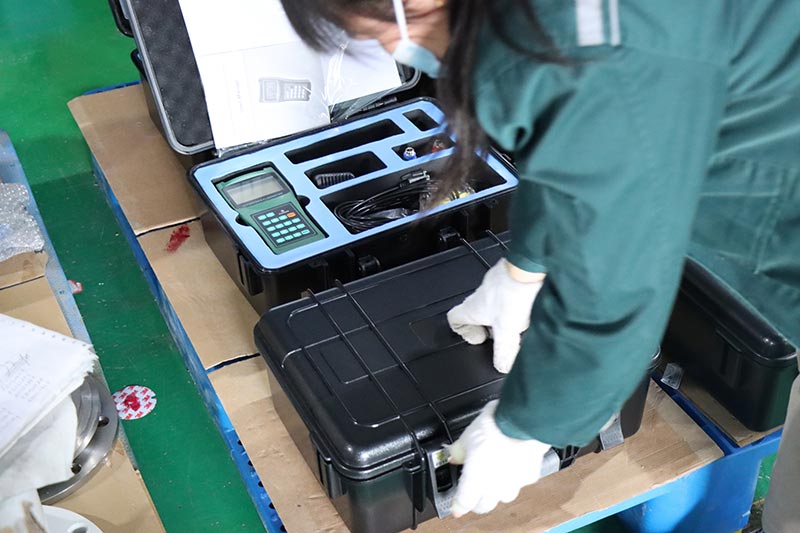

Flowmeter Water Wall Mounted Clamp On Ultrasonic Flow Meter Digital Water

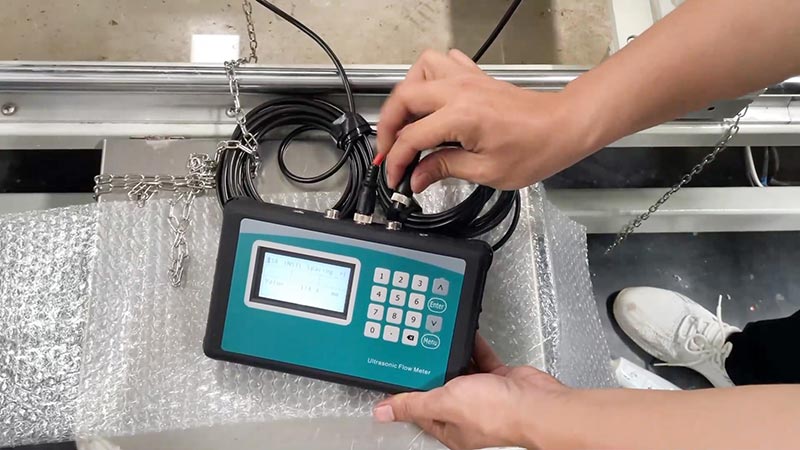

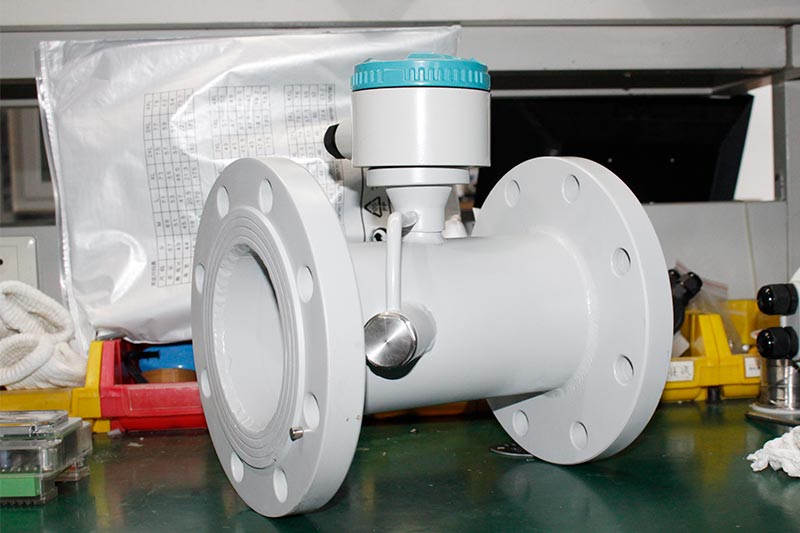

Flowmeter Water Wall Mounted Clamp On Ultrasonic Flow Meter Digital Water measure flow by propagating ultrasonic waves into a liquid-filled pipe. These wall mounted flowmeter are located outside the pipeline and offer a wide range of pipeline sizes with no pressure loss, no contact with the liquid inside, and no moving parts.

Accuracy: +/-1.0% of FS

Wide range: DN15mm-DN6000mm

None cut down pipe

Power supply: 24VDC/85VAC-2265AC

Communication: RS485

Contact US

Get Price

Share:

Content

Technical Data

Table 1:Wall Mount Type Ultrasonic Flow Meter Technology Parameter

| Items | Specifications |

| Accuracy | ±1% of reading at rates >0.2 mps |

| Repeatability | 0.2% |

| Principle | Transmit time |

| Velocity | ±32m/s |

| Pipe Size | DN15mm-DN6000mm |

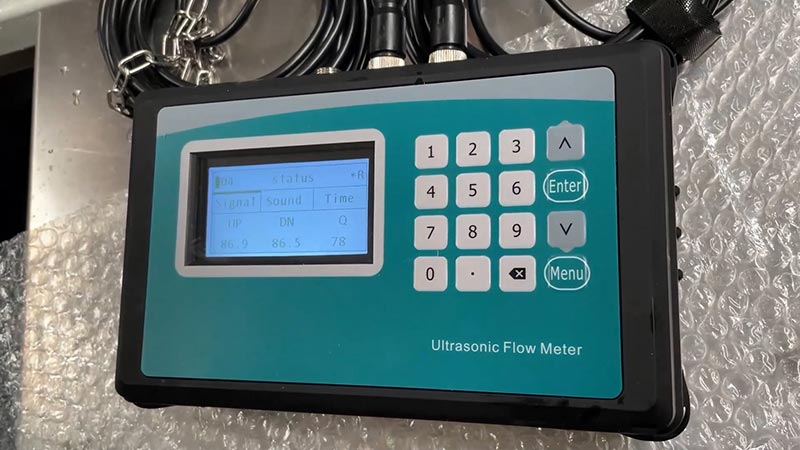

| Display | LCD with backlight, display accumulated flow/heat, instantaneous flow/heat, velocity, time etc. |

| Signal Output | 1 way 4-20mA output |

| 1 way OCT pulse output | |

| 1 way relay output | |

| Signal Input | 3 way 4-20mA input achieve to heat measurement by connecting PT100 platinum resistor |

| Other Functions | Automatically record the positive,negative,net totalizer flow rate and heat. Automatically record the time of power-on/off and flow rate of the last 30 times.Replenish by hand or read the datas through Modbus communication protocol. |

| Pipe Material | Carbon Steel, stainless steel, cast iron, cement pipe, copper, PVC, aluminum, FRP etc. Liner is allowed |

| Straight Pipe Section | Upstram: 10D; Downsteam:5D; From the pump:30D (D means outer diameter) |

| Liquid Types | Water, sea water, industrial sewage, acid & alkali liquid, alcohol, beer, all kinds of oils which can transmit ultrasonic single uniform liquid |

| Liquid Temperature | Standard: -30℃ ~ 90℃ ,High-temperature:-30℃ ~ 160℃ |

| Liquid Turbidity | Less than 10000ppm, with a little bubble |

| Flow Direction | Bi-directional measuring, net flow/heat measuring |

| Environment Temperature | Main Unit: -30℃ ~ 80℃ |

| Transducer: -40℃ ~ 110℃, Temperature transducer: select on enquiry | |

| Environment Humidity | Main Unit: 85% RH |

| Transducer: standard is IP65, IP68(optional) | |

| Cable | Twisted Pair Line, standard length of 5m, can be extended to 500m (not recommended); Contact the manufacturer for longer cable requirement. RS-485 interface, transmission distance up to 1000m |

| Power Supply | AC220V and DC24V |

| Power Consumption | Less than 1.5W |

| Communication | MODBUS RTU RS485 |

Table 2: Wall Mount Type Ultrasonic Flow Meter Transducer Selection

| Type | Picture | Specification | Measuring range | Temperature range |

| Clamp on type | .png) |

Small-size | DN15mm~DN100mm | -30℃~90℃ |

.png) |

Middle- size | DN50mm~DN700mm | -30℃~90℃ | |

.png) |

Large -size | DN300mm~DN6000mm | -30℃~90℃ | |

| High temperature clamp on type |

.png) |

Small-size | DN15mm~DN100mm | -30℃~160℃ |

.png) |

Middle- size | DN50mm~DN700mm | -30℃~160℃ | |

.png) |

Large -size | DN300mm~DN6000mm | -30℃~160℃ | |

| Insert type | .png) |

standard length type Wall thickness ≤20mm |

DN50mm~DN6000mm | -30℃~160℃ |

.png) |

Extra-length type Wall thickness ≤70mm |

DN50mm~DN6000mm | -30℃~160℃ | |

.png) |

Parallel type used for narrow installation space |

DN80mm~DN6000mm | -30℃~160℃ | |

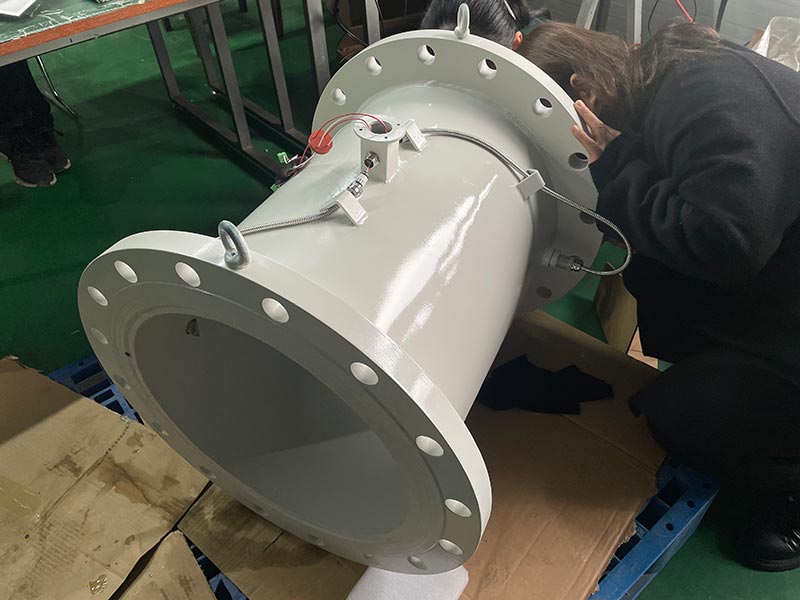

| Inline type | .png) |

π type inline | DN15mm~DN32mm | -30℃~160℃ |

.png) |

Flange type | DN40mm~DN1000mm | -30℃~160℃ |

Table 3: Wall Mount Type Ultrasonic Flow Meter Temperature Sensor Model

| PT100 | Picture | Accuracy | Cut off water | Measuring range | Temperature |

| clamp on | .png) |

±1% | No | DN50mm~DN6000mm | -40℃~160℃ |

| Insertion sensor | .png) |

±1% | Yes | DN50mm~DN6000mm | -40℃~160℃ |

| Insertion type installation with pressure | .png) |

±1% | No | DN50mm~DN6000mm | -40℃~160℃ |

| Insertion type for small pipe diameter | .png) |

±1% | Yes | DN15mm~DN50mm | -40℃~160℃ |

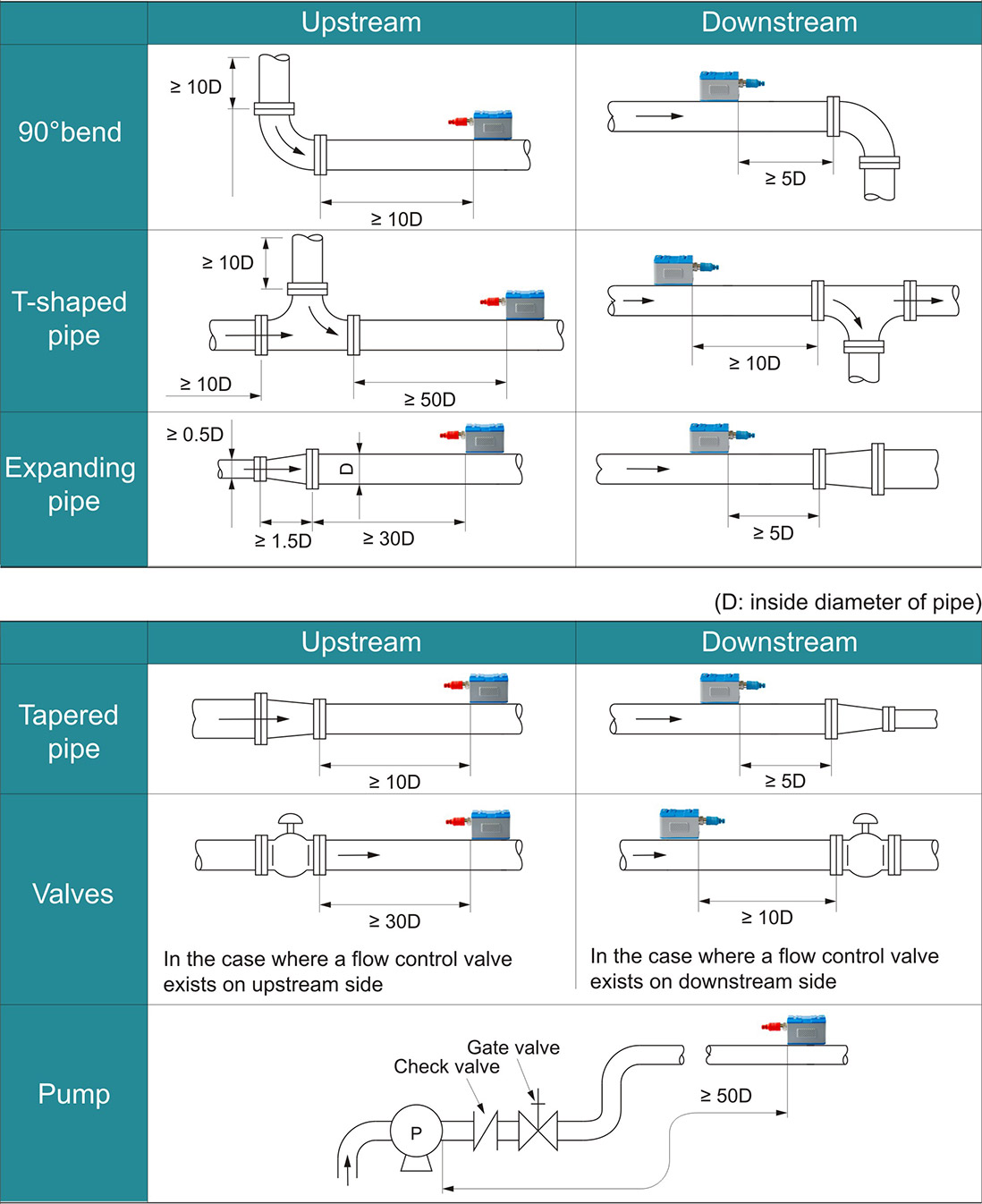

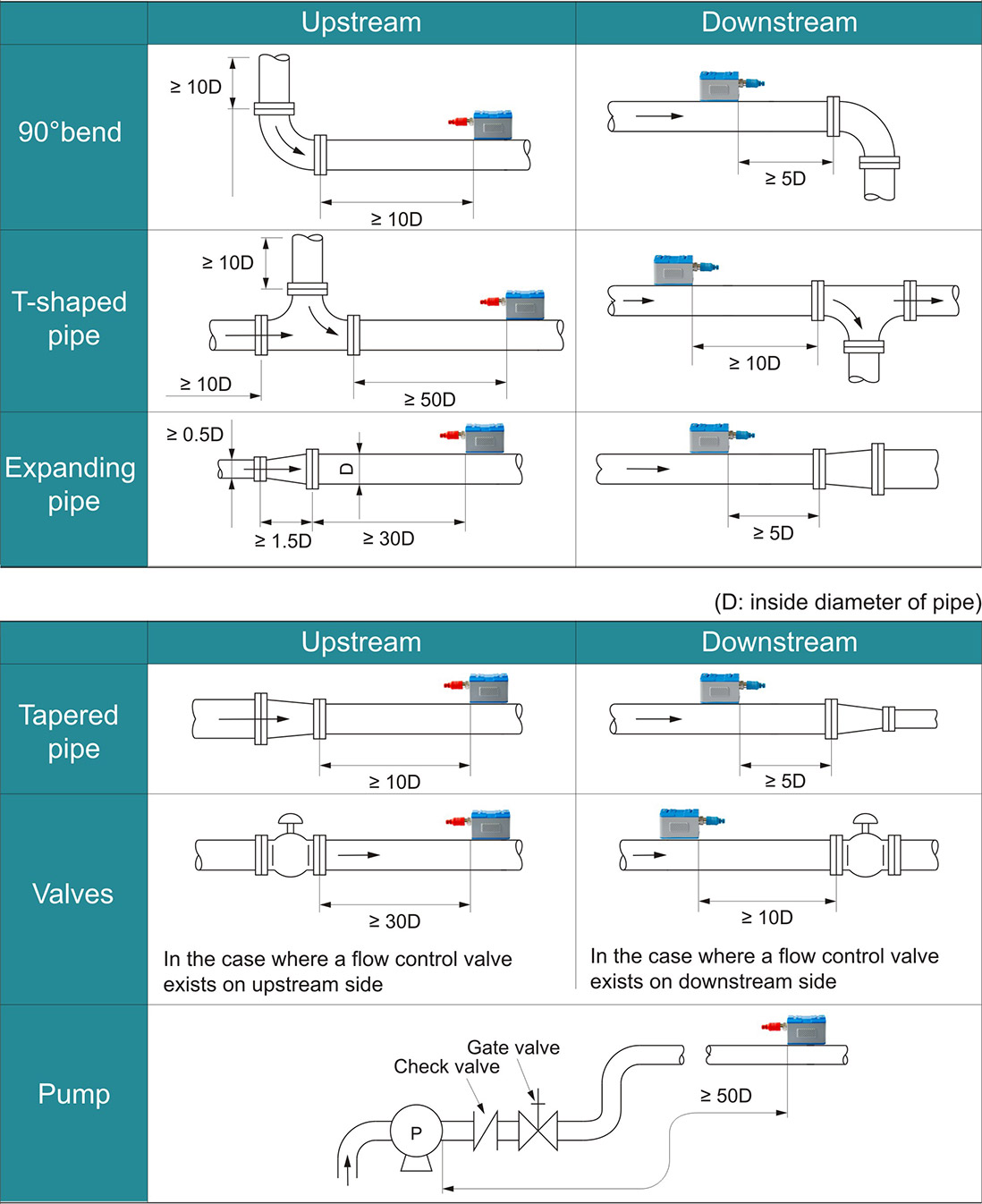

Installation

Wall mount type ultrasonic flow meter installation requirements

The state of the pipeline for measuring the flow will greatly affect the measurement accuracy, the detector installation location should be selected in a place that meets the following conditions:

1. It must be ensured that the straight pipe section where the probe is installed is: 10D on the upstream side(D is the pipe diameter), 5D or more on the downstream side, and there must be no factors that disturb the fluid(such as pumps,valves, throttles, etc.) in the 30D on the upstream side. And try to avoid the unevenness and welding position of the pipeline under test.

2. The pipeline is always full of liquid, and the fluid should not contain bubbles or other foreign objects. For horizontal pipelines, install the detector within ±45°of the horizontal centerline. Try to choose the horizontal centerline position.

3. When install the ultrasonic flow meter, need to input these parameters: pipe material,pipe wall thickness and pipe diameter. Fulid type, whether it contains impurities,bubbles, and whether the tube is full.

The state of the pipeline for measuring the flow will greatly affect the measurement accuracy, the detector installation location should be selected in a place that meets the following conditions:

1. It must be ensured that the straight pipe section where the probe is installed is: 10D on the upstream side(D is the pipe diameter), 5D or more on the downstream side, and there must be no factors that disturb the fluid(such as pumps,valves, throttles, etc.) in the 30D on the upstream side. And try to avoid the unevenness and welding position of the pipeline under test.

2. The pipeline is always full of liquid, and the fluid should not contain bubbles or other foreign objects. For horizontal pipelines, install the detector within ±45°of the horizontal centerline. Try to choose the horizontal centerline position.

3. When install the ultrasonic flow meter, need to input these parameters: pipe material,pipe wall thickness and pipe diameter. Fulid type, whether it contains impurities,bubbles, and whether the tube is full.

Transducers installation

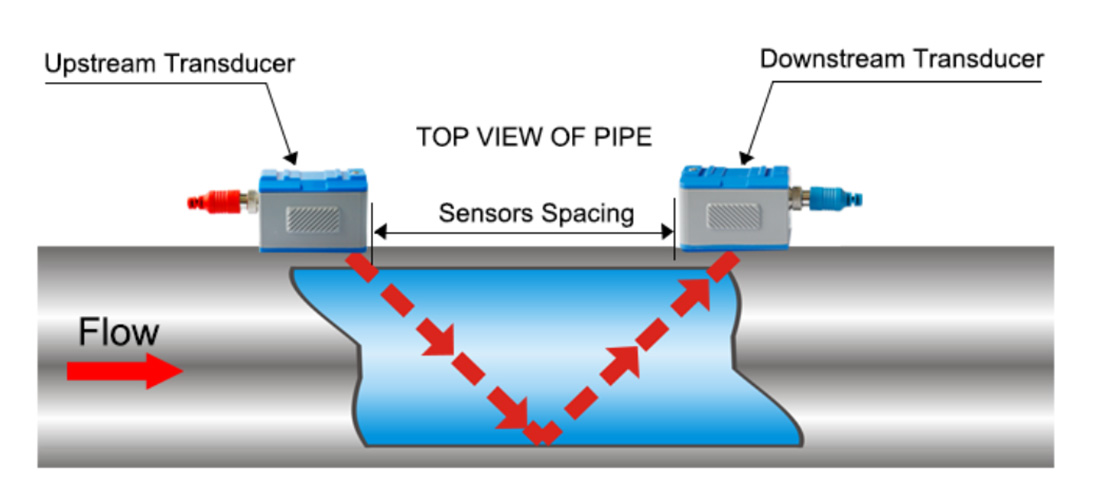

1. V-method Installation

V-method installation is the most widely used mode for daily measurement with pipe inner diameters ranging from DN15mm ~ DN200mm. It is also called reflective mode or method.

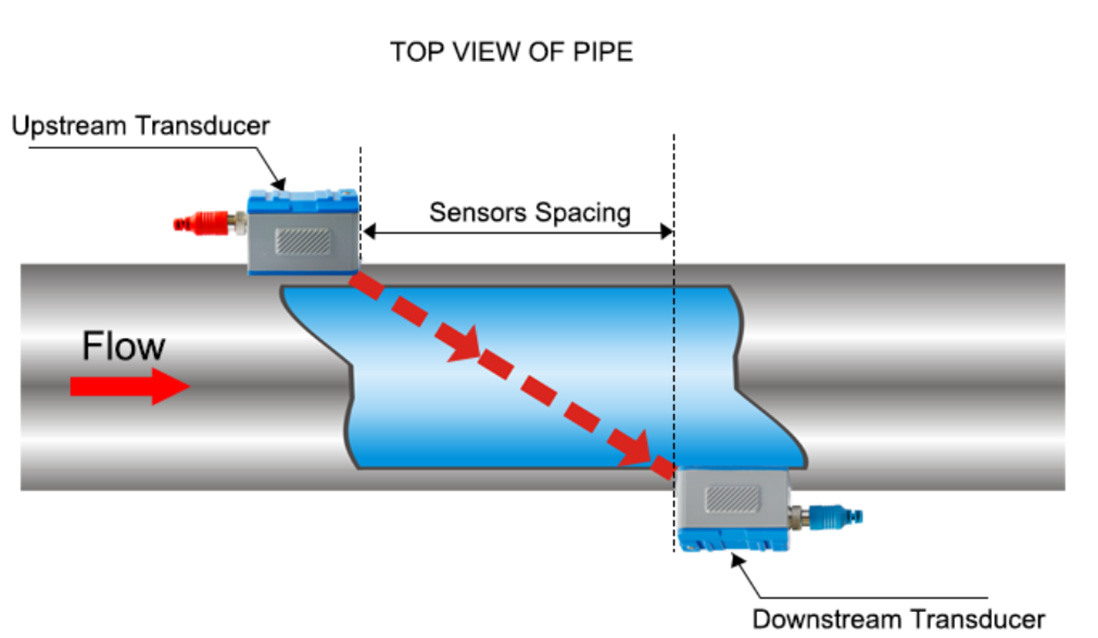

2. Z-method Installation

Z-method is commonly used when the pipe diameter is above DN300mm.

Inquiry

More Ultrasonic Flow Meter