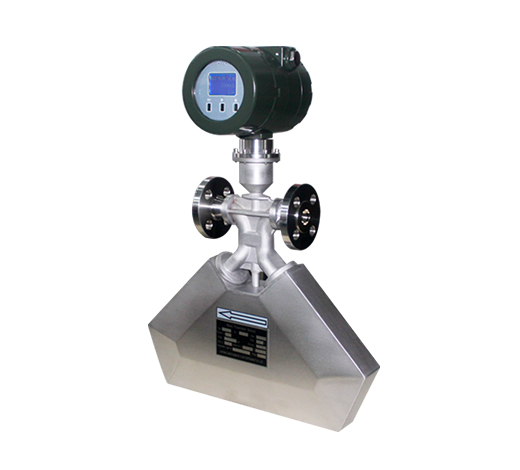

The Coriolis flow meter worked on the Coriolis effect and was named. Coriolis flow meters are considered to be true mass flow meters because they tend to measure mass flow directly, while other flow meter techniques measure volume flow.

Besides, with batch controller, it can directly control the valve in two stages. Therefore, Coriolis mass flowmeters are widely used in chemical, pharmaceutical, energy, rubber, paper, food and other industrial sectors, and are quite suitable for batching, loading and custody transfer.