|

Caliber (mm) |

20 | 25 | 32 | 50 | 80 | 100 | 150 | 200 |

|

Flow Range (m3/h) |

1.2~15 | 2.5~30 | 4.5~60 | 10~150 | 28~400 | 50~800 | 150~2250 | 360~3600 |

|

Accuracy |

1.0~1.5% | |||||||

|

Repeatability |

Less than 1/3 of basic error absolute value |

|||||||

|

Working Pressure (MPa) |

1.6Mpa, 2.5Mpa, 4.0Mpa, 6.3Mpa Special pressure please double check |

|||||||

|

Application Condition |

Environment temperature: -30℃~+65℃ Relative humidity: 5%~95% Medium temperature: -20℃~+80℃ Atmospheric pressure: 86KPa~106KPa |

|||||||

|

Working Power |

24VDC+3.6V battery power, can remove the battery | |||||||

| Output Signal | 4-20mA, pulse, RS485, alarm | |||||||

| Applicable Medium | All gases (except steam) | |||||||

| Explosion-proof Mark | Ex ia II C T6 Ga | |||||||

|

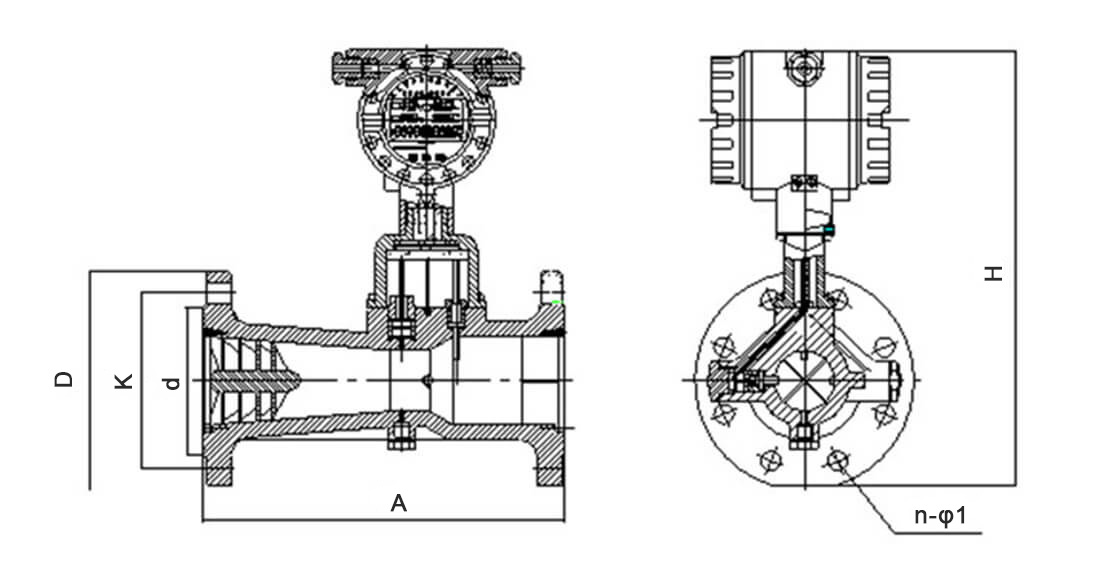

Caliber (mm) |

Length (mm) |

PN1.6~4.0MPa |

|||||||||||||||||

| H | Dφ | Kφ | N | L | dφ | H | Dφ | Kφ | N | L | dφ | H | Dφ | Kφ | N | L | dφ | ||

| 25 | 200 | 305 | 115 | 85 | 4 | 14 | 65 | ||||||||||||

| 32 | 200 | 320 | 140 | 100 | 4 | 18 | 76 | ||||||||||||

| 50 | 230 | 330 | 165 | 125 | 4 | 18 | 99 | ||||||||||||

| 80 | 330 | 360 | 200 | 160 | 8 | 18 | 132 | ||||||||||||

| PN1.6MPa | ※PN2.5~4.0MPa | ||||||||||||||||||

| 100 | 410 | 376 | 220 | 180 | 8 | 18 | 156 | 390 | 235 | 190 | 8 | 22 | 156 | ||||||

| 150 | 570 | 430 | 285 | 240 | 8 | 22 | 211 | 450 | 300 | 250 | 8 | 26 | 211 | ||||||

| PN1.6MPa | PN2.5MPa | ※PN4.0MPa | |||||||||||||||||

| 200 | 700 | 470 | 340 | 295 | 12 | 22 | 266 | 490 | 360 | 310 | 12 | 26 | 274 | 510 | 375 | 320 | 12 | 30 | 284 |

| DN(mm) | Type | Flow Range (m³/h) |

Working Pressure (MPa) | Accuracy Level | Repeatability |

| 20 | 1.2~15 | 1.6 2.5 4.0 6.3 |

1.0 1.5 |

Less than 1/3 of basic error absolute value | |

| 25 | 2.5~30 | ||||

| 32 | 4.5~60 | ||||

| 50 | B | 10~150 | |||

| 80 | B | 28~400 | |||

| 100 | B | 50~800 | |||

| 150 | B | 150~2250 | |||

| 200 | 360~3600 |

| LUGB | XXX | X | X | X | X | X | X | X | X | X | |

| Caliber (mm) |

DN25-DN200 Reference Code, please check caliber code table 1 |

||||||||||

| Function | With temperature & pressure compensation | Y | |||||||||

| Without temperature & pressure compensation | N | ||||||||||

| Nominal Pressure |

1.6Mpa | 1 | |||||||||

| 2.5Mpa | 2 | ||||||||||

| 4.0Mpa | 3 | ||||||||||

| 6.3Mpa | 4 | ||||||||||

| Others | 5 | ||||||||||

| Connection | Flange | 1 | |||||||||

| Thread | 2 | ||||||||||

| WAFER | 3 | ||||||||||

| Others | 4 | ||||||||||

| Output Signal | 4-20mA,pulse (two-wire system) | 1 | |||||||||

| 4-20mA,pulse (three-wire system) | 2 | ||||||||||

| RS485 communication | 3 | ||||||||||

| 4-20mA, pulse,HART | 4 | ||||||||||

| Others | 5 | ||||||||||

| Alarm | Low and high limit Alarm | 6 | |||||||||

| Without | 7 | ||||||||||

| Accuracy Level | 1.0 | 1 | |||||||||

| 1.5 | 2 | ||||||||||

| Cable Entry | M20X1.5 | M | |||||||||

| 1/2'' NPT | N | ||||||||||

| Structure Type |

Compact/Integral | 1 | |||||||||

| Remote | 2 | ||||||||||

| Power Supply |

3.6V Lithium Battery,DC24V | A | |||||||||

| DC24V | D | ||||||||||

| 3.6V Lithium Battery | E | ||||||||||

| Ex-proof | With Ex-proof | 0 | |||||||||

| Without Ex-proof | 1 | ||||||||||

| Shell Material | Stainless Steel | S | |||||||||

| Aluminium Alloy | L | ||||||||||

| Process Connection |

DIN PN16 | 1 | |||||||||

| DIN PN25 | 2 | ||||||||||

| DIN PN40 | 3 | ||||||||||

| ANSI 150# | 4 | ||||||||||

| ANSI 300# | A | ||||||||||

| ANSI 600# | B | ||||||||||

| JIS 10K | C | ||||||||||

| JIS 20K | D | ||||||||||

| JIS 40K | E | ||||||||||

| Others | F | ||||||||||

.jpg)