Q&T Liquid Turbine Flow Meter is internally developed and perfected by Q&T Instrument. Over the years, Q&T Liquid Turbine Flow Meter has been commissioned in many parts of the world, received praise from end-users and industrial leaders.

Q&T Instrument Turbine Flow Meter offers two accuracy classes, 0.5%R and 0.2%R. Its simple structure allows a small pressure loss and virtually no maintenance requirements.

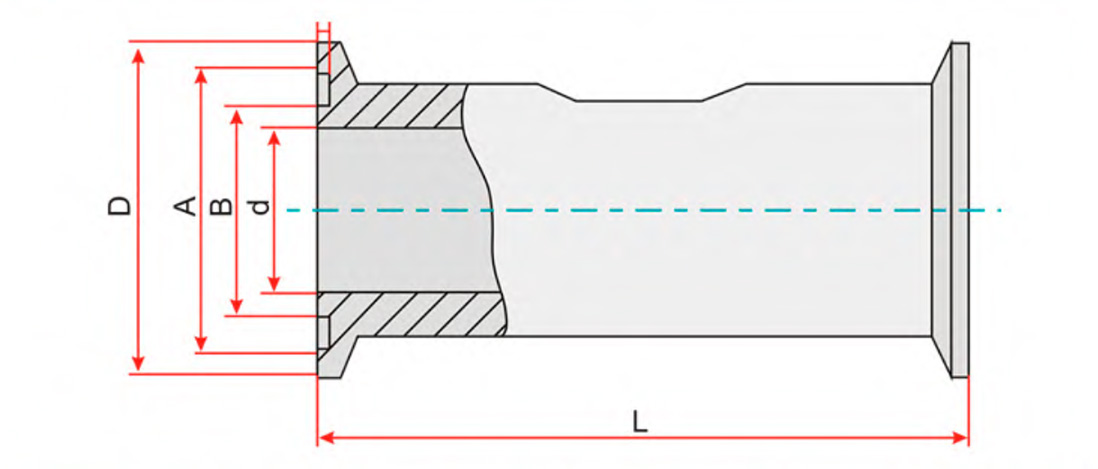

The Tri-Clamp Turbine Flow Meter offers two types of converter options, Compact Type (Direct Mount) and Remote Type. Our users can select the preferred converter type depending on the commissioning environment. Q&T Tri-Clamp Turbine flow meter is the most popular turbine product used to measure clean oil and water. Thus it is often referred to as a Sanitary type Turbine meter.

(1).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)