The ultrasonic velocity in gas is influenced by the gas temperature,So the level meter need to detect the gas temperature at work. So the material level meter need to detect the gas temperature at work,compensation for sound velocity.

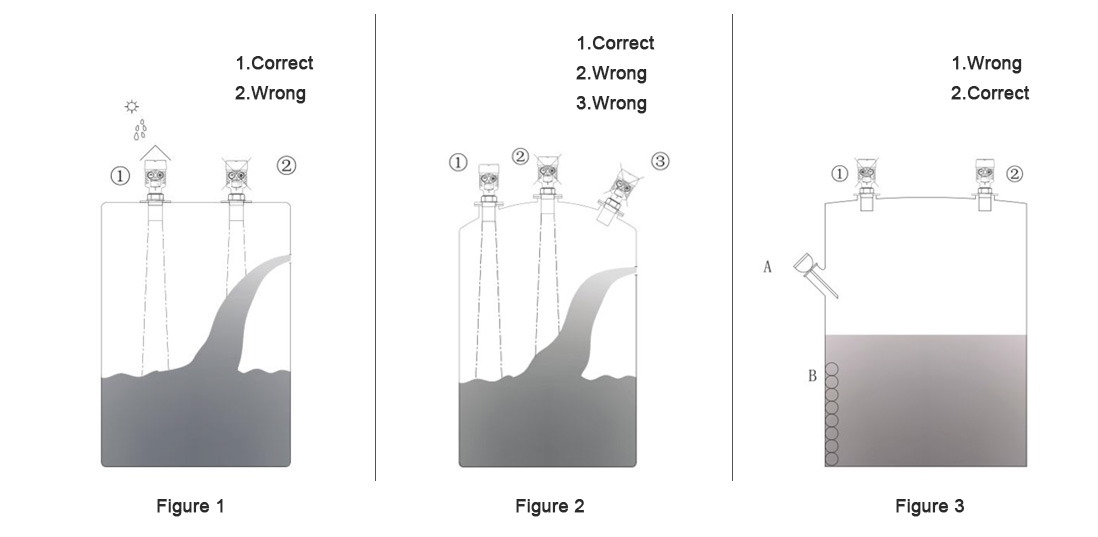

The sensor of the meter pulses in the direction of the product surface. There, they are reflected back and received by the sensor.

.jpg)

.jpg)

.jpg)

.jpg)