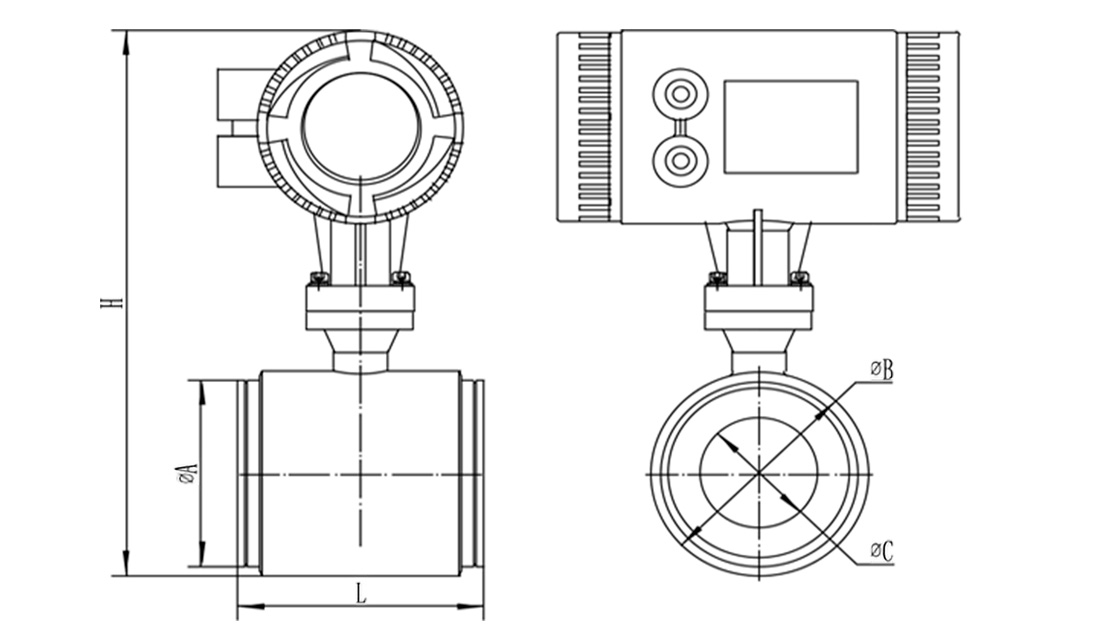

Wafer Electromagnetic Flow Meter Installation & Maintainance

1. Installation

First of all, we need choose a pair of matching flanges. Then connect the flow meter with pipeline.

Wafer electromagnetic flow meter should be installed correctly to ensure good measurement. Normally we need leave 10D(10 times of diameter) straight pipe distance before wafer electromagnetic flow meter and 5D behind wafer electromagnetic flow meter.

And try to avoid elbow/valve/pump or other device which will influent the flow speed. If the distance is not enough, then please install flow meter according to follow picture.

.jpg)

lnstall at the lowest point and vertical upward direction

Don't install at the highest point or vertical downward diection |

.jpg)

When drop is more than 5m, install exhaust

valve at the downstream |

.jpg)

lnstall at the lowest point when used in open drain pipe |

.jpg)

Need 10D of upstream and 5D of downstream |

.jpg)

Dont' install it at the entrance of pump, install it at the exit of pump |

.jpg)

lnstall at the rising direction |

2. Maintenance

Routine maintenance: only need to make periodic visual inspections of the instrument, check the environment around the instrument, remove dust and dirt, ensure that no water and other substances enter, check whether the wiring is in good condition, and check whether there are newly installed strong electromagnetic field equipment or newly installed wires near the instrument Cross-instrument. If the measuring medium easily contaminates the electrode or deposits in the measuring tube wall, it should be cleaned and cleaned regularly.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)