.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

| Measuring range |

Water (20℃) 16~150000 l/h. Air(0.1013MPa 20℃) 0.5~4000 m3/h. |

| Range ratio | 10:1(Special type 20:1). |

| Accuracy class | 2.5(Special type 1.5% or 1.0%). |

| Working pressure |

DN15~DN50 PN16 (Special type 2.5MPa). DN80~DN150 PN10 (Special type 1.6MPa). Pressure rating of jacket 1.6MPa. |

| Medium temperature |

Normalized type -80℃~+220℃. High-temperature type 300℃. Lined with FEP type ≤85℃. |

| Ambient temperature |

-40℃~+120℃(Remote display without LCD≤85℃). (Remote display with LCD≤70℃). |

| Dielectric viscosity |

1/4” NPT, 3/8” NPT 1/2” NPT≤5mPa.s 3/4” NPT,1” NPT ≤250mPa.s |

| Output |

Standard signal: two-wire system 4 ~ 20mA (with HART communication). Standard signal: three-wire system 0 ~ 10mA. Alarm signal:1.Two-way relay output. 2.One-way or two-approach switches . Pulse signal output: 0-1KHz isolated output. |

| Process connection |

Standard type:24VDC±20%. AC type:220VAC(85~265VAC) (optional). |

| Connection mode |

Flange Thread Tri-clamp |

| Levels of protection |

IP65/IP67. |

| Ex-mark |

Intrinsically safe:ExiaIICT3~6. Exd type:ExdIICT4~6. |

|

Caliber (mm) |

Work number | Flow range | Pressure loss kpa | ||||

|

Water L/h |

Air m3/h | Water Kpa | Air | ||||

| Normal type | Anti-corrossion type | Normal type Anti-corrossion type |

Normal type |

Anti-corrossion type | |||

| 15 | 1A | 2.5~25 | -- | 0.07~0.7 | 6.5 | - | 7.1 |

| 1B | 4.0~40 | 2.5~25 | 0.11~1.1 | 6.5 | 5.5 | 7.2 | |

| 1C | 6.3~63 | 4.0~40 | 0.18~1.8 | 6.6 | 5.5 | 7.3 | |

| 1D | 10~100 | 6.3~63 | 0.28~2.8 | 6.6 | 5.6 | 7.5 | |

| 1E | 16~160 | 10~100 | 0.48~4.8 | 6.8 | 5.6 | 8.0 | |

| 1F | 25~250 | 16~160 | 0.7~7.0 | 7.0 | 5.8 | 10.8 | |

| 1G | 40~400 | 25~250 | 1.0~10 | 8.6 | 6.1 | 10.0 | |

| 1H | 63~630 | 40~400 | 1.6~16 | 11.1 | 7.3 | 14.0 | |

| 25 | 2A | 100~1000 | 63~630 | 3~30 | 7.0 | 5.9 | 7.7 |

| 2B | 160~1600 | 100~1000 | 4.5~45 | 8.0 | 6.0 | 8.8 | |

| 2C | 250~2500 | 160~1600 | 7~70 | 10.8 | 6.8 | 12.0 | |

| 2D | 400~4000 | 250~2500 | 11~110 | 15.8 | 9.2 | 19.0 | |

| 40 | 4A | 500~5000 | 300~3000 | 12~120 | 10.8 | 8.6 | 9.8 |

| 4B | 600~6000 | 350~3500 | 16~160 | 12.6 | 10.4 | 16.5 | |

| 50 | 5A | 630~6300 | 400~4000 | 18~180 | 8.1 | 6.8 | 8.6 |

| 5B | 1000~10000 | 630~6300 | 25~250 | 11.0 | 9.4 | 10.4 | |

| 5C | 1600~16000 | 1000~10000 | 40~400 | 17.0 | 14.5 | 15.5 | |

| 80 | 8A | 2500~25000 | 1600~16000 | 60~600 | 8.1 | 6.9 | 12.9 |

| 8B | 4000~40000 | 2500~25000 | 80~800 | 9.5 | 8.0 | 18.5 | |

| 100 | 10A | 6300~63000 | 4000~40000 | 100~1000 | 15.0 | 8.5 | 19.2 |

| 150 | 15A | 20000~100000 | -- | 600~3000 | 19.2 | -- | 20.3 |

| QTLZ | X | X | X | X | X | X | X | X | X |

| Indicator | Code | ||||||||

| Local indicator | Z | ||||||||

| LCD indicator with ouput | D | ||||||||

| Norminal diameter | Code | ||||||||

| DN15 | -15 | ||||||||

| DN20 | -20 | ||||||||

| DN25 | -25 | ||||||||

| DN40 | -40 | ||||||||

| DN50 | -50 | ||||||||

| DN80 | -80 | ||||||||

| DN100 | -100 | ||||||||

| DN150 | -150 | ||||||||

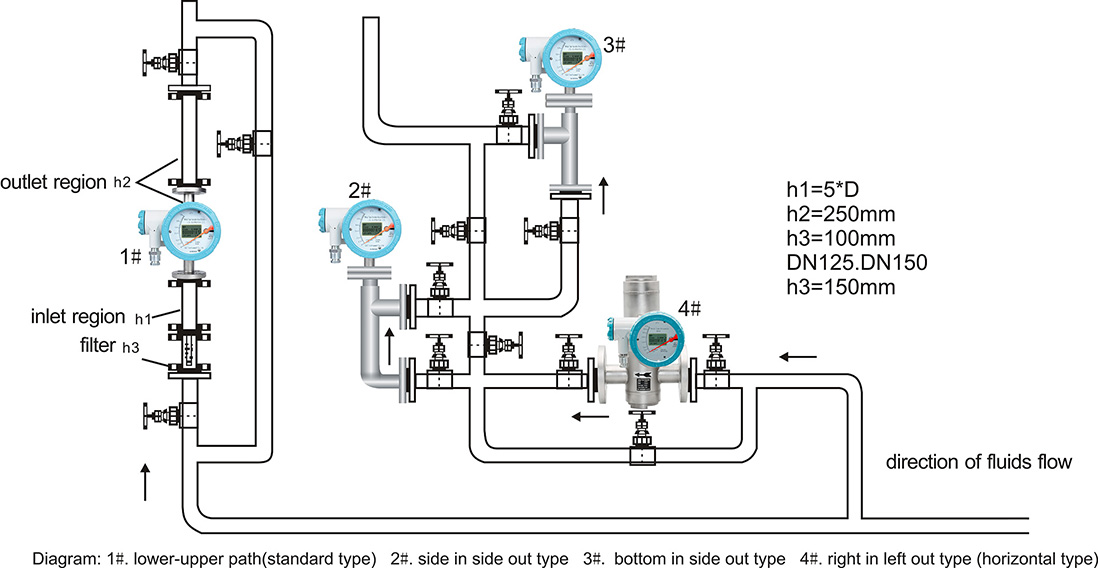

| Structure | Code | ||||||||

| Bottom-top | / | ||||||||

| Left-right (horizontal) | H1 | ||||||||

| Right-left (horizontal) | H2 | ||||||||

| Side-side | AA | ||||||||

| Bottom -side | LA | ||||||||

| Thread connection | S | ||||||||

| Tri-clamp | M | ||||||||

| Body material | Code | ||||||||

| 304SS | R4 | ||||||||

| 316LSS | R6L | ||||||||

| Hastelloy C | Hc4 | ||||||||

| Titanium | Ti | ||||||||

| Liner F46(PTFE) | F | ||||||||

| Monel | M | ||||||||

| Indicator type | Code | ||||||||

| Iinear indicator(pointer indication) | M7 | ||||||||

| Nonlinear indicator(LCD Display) | M9 | ||||||||

| Combination function(only for LCD display) | Code | ||||||||

| 24VDC with 4~20mA output | S | ||||||||

| 24VDC with HART communication | Z | ||||||||

| Battery power | D | ||||||||

| Additional function | Code | ||||||||

| Measuring tube with thermal preservation / heat insulation jacket | T | ||||||||

| Measure medium temperature higher than 120.C | HT | ||||||||

| Ex-proof: | Code | ||||||||

| With | W | ||||||||

| Without | N | ||||||||

| Alarm | Code | ||||||||

| One alarm | K1 | ||||||||

| Two alarm | K2 | ||||||||

| None | N | ||||||||