Is popular in industrial applications is the way they are designed and built. The feature is no moving parts, nearly unobstructed straight through flow path, require no temperature or pressure corrections and retain accuracy over a wide range of flow rates. Straight pipe runs can be reduced by using dual-plate flow conditioning elements and installation is very simple with minimal pipe intrusions.

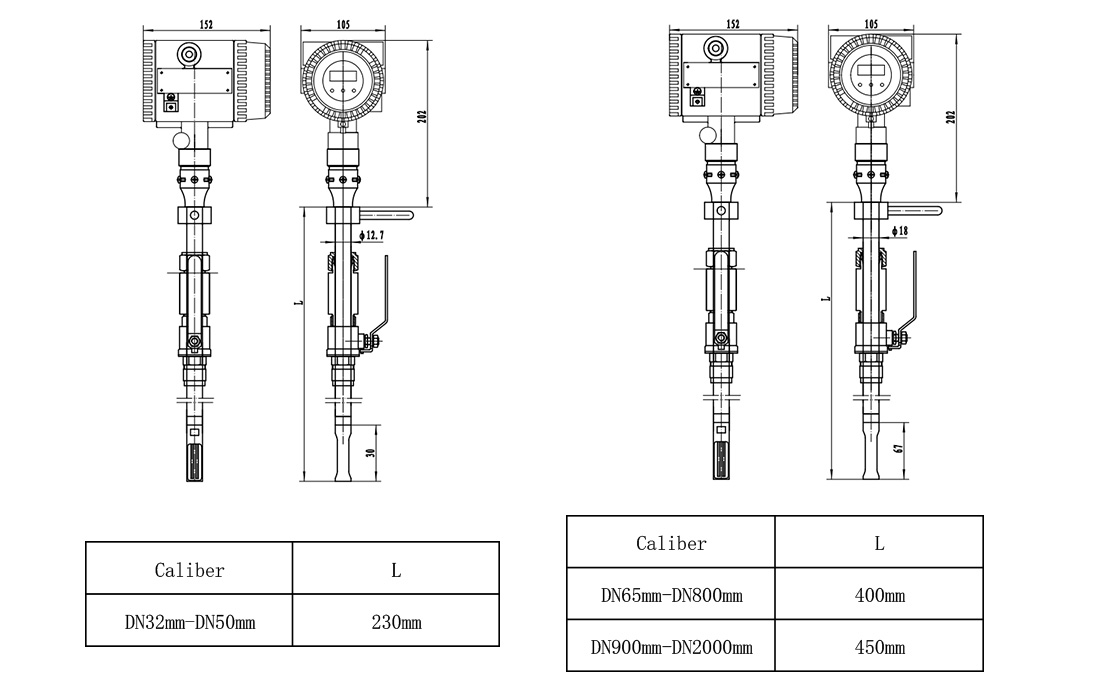

Insertion type thermal gas mass flow meter size from DN40~DN2000mm.

.jpg)

.jpg)