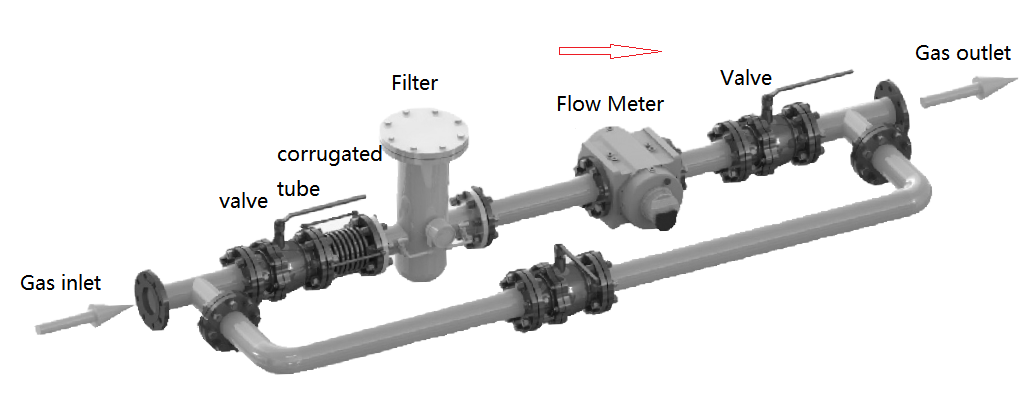

QTLL intelligent gas roots flow meter is a flow meter that integrates flow, pressure and temperature detection functions which could perform pressure, temperature and compression factor correction. It has a variety of structural forms and functional configurations to meet the different requirements of users. QTLL gas roots flow meter is widely used in the fields of urban gas and industrial gas flow measurement and detection, and could meet the user's requirements for high-precision, high-reliability measurement or detection.

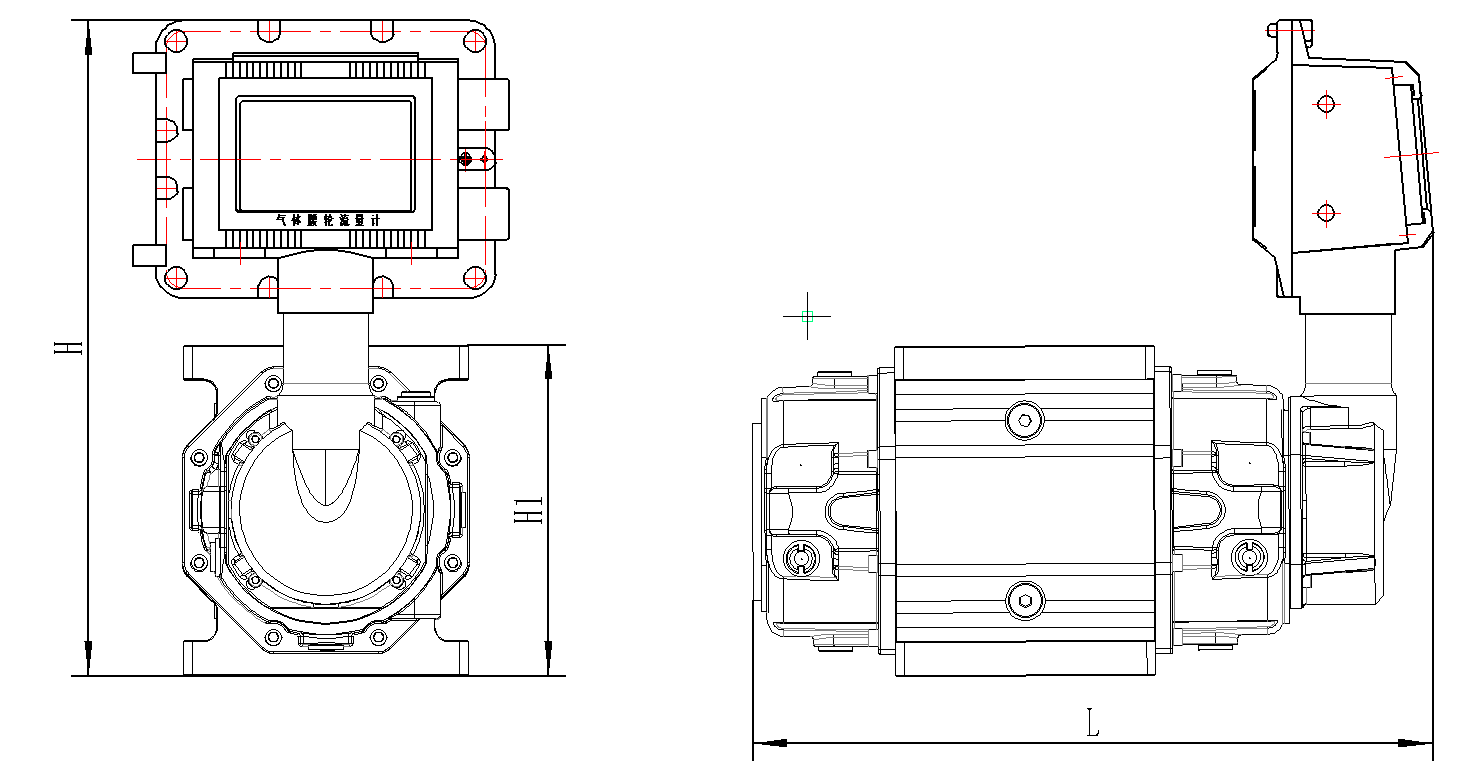

Vertical installation.png)