Q&T handheld ultrasonic flow meter realizes non-contact measurement of liquid flow. Install the sensor on the outer wall of the pipeline to complete the flow measurement. It has the characteristics of small size. Convenient carrying and accurate measurement.

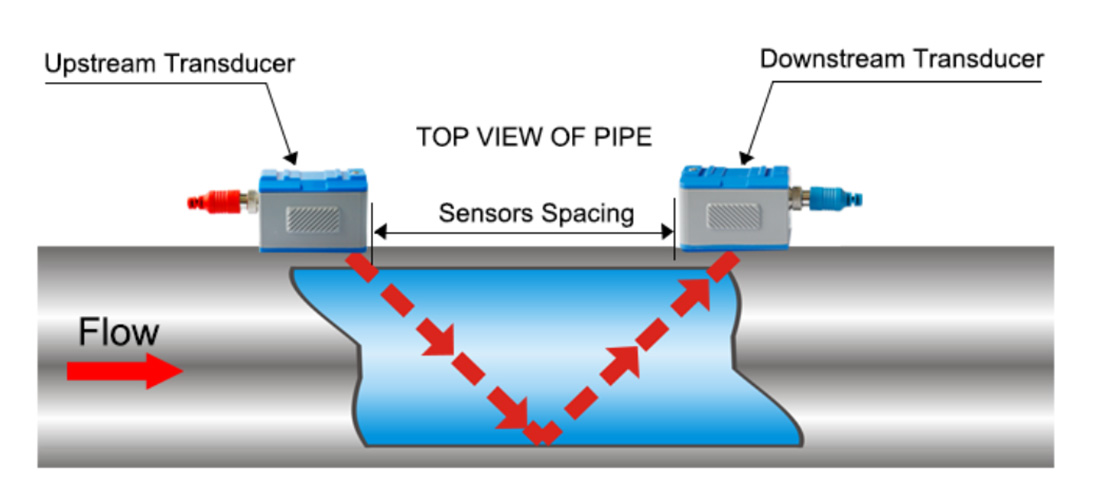

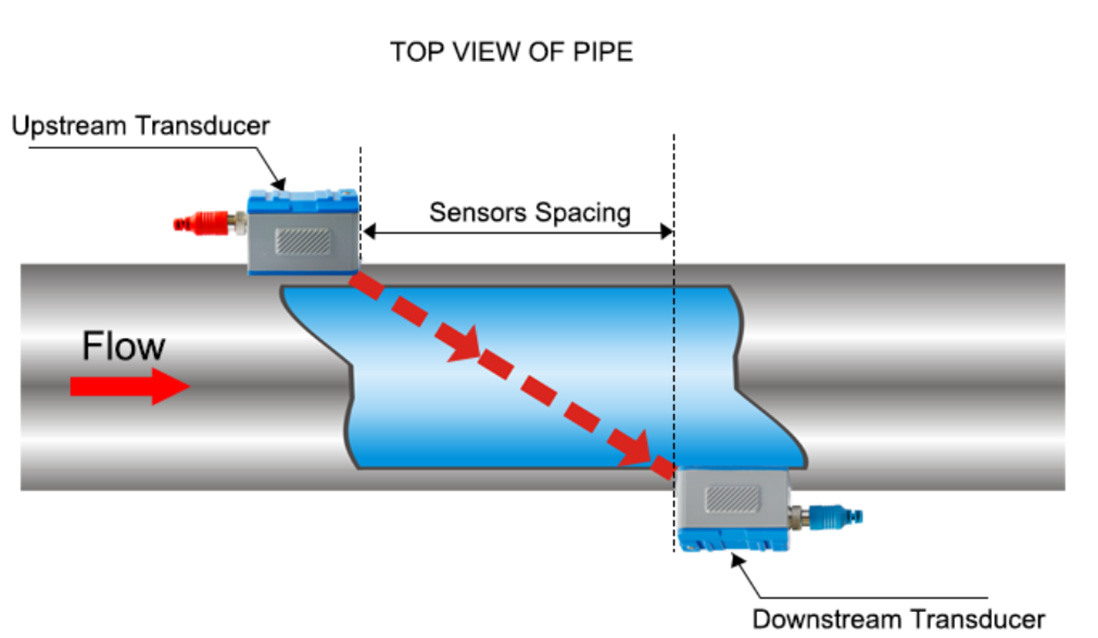

Handheld Ultrasonic Flow meter Principle Working: Time-transit measurement principle is adopted, the signal transmitted by one flow meter transducer passes through the pipe wall, the medium, and the other side pipe wall, and is received by another flow meter transducer. At the same time, the second transducer also transmits the signal received by the first transducer. The influence of the medium flow rate, there is a time difference, and then the flow value Q can be obtained.

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)