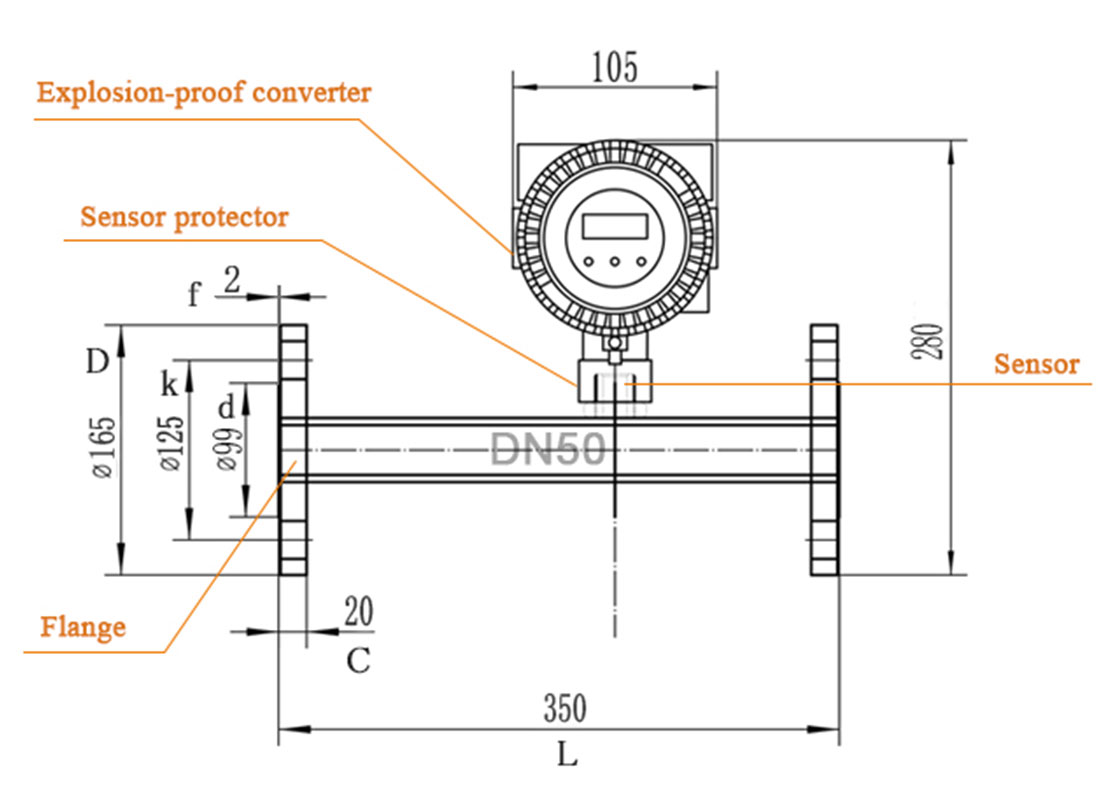

Flange thermal gas mass flow meter installation:

① Observe the recommended inlet and outlet requirements.

② Good engineering practice is necessary for the associated pipe work and installation.

③ Ensure correct alignment and orientation of the sensor.

④ Take measures to reduce or avoid condensation (e.g. install a condensation trap, thermal insulation, etc.).

⑤ The maximum permitted ambient temperatures and the medium temperature range must be observed.

⑥ Install the transmitter in a shaded location or use a protective sun shield.

⑦ For mechanical reasons, and in order to protect the pipe, it is advisable to support heavy sensors.

⑧ No installation in where large vibration exists

⑨ No exposure in the environment containing a lot of corrosive gas

⑩ No sharing power supply with frequency converter, electric welding machine and other machines which can make power-line interference.

Daily maintenance for flange thermal gas mass flow meter:

In the daily operation of the thermal gas mass flowmeter, check and clean the flowmeter, tighten the loose parts, find and deal with the abnormality of the flowmeter in operation in time, ensure the normal operation of the flowmeter, reduce and delay the wear of components, Extend the service life of the flowmeter. Some flowmeters will become fouling after being used for a period of time, and it must be cleaned by pickling etc. depending on the degree of fouling

.jpg)

.jpg)