1. Electromagnetic flowmeter output signal is very small, usually only a few millivolts. In order to improve the anti-interference ability of the instrument, the zero potential in the input circuit must be zero potential with the ground potential, which is a sufficient condition for the sensor to be grounded. Poor grounding or no grounding wire will cause external interference signals and cannot be measured normally.

2. The grounding point of the electromagnetic sensor should be electrically connected to the measured medium, which is a necessary condition for the electromagnetic flowmeter to work. If this condition is not met, the electromagnetic flowmeter cannot work normally, which is determined by the signal circuit of the sensor. When the fluid cuts the magnetic wire to generate a flow signal, the fluid itself acts as a zero potential, one electrode generates a positive potential, the other electrode generates a negative potential, and it changes alternately. Therefore, the midpoint of the converter input (signal cable shield) must be at zero potential and conducting with the fluid to form a symmetrical input circuit. The midpoint of the input end of the converter is electrically connected to the measured fluid through the ground point of the sensor output signal.

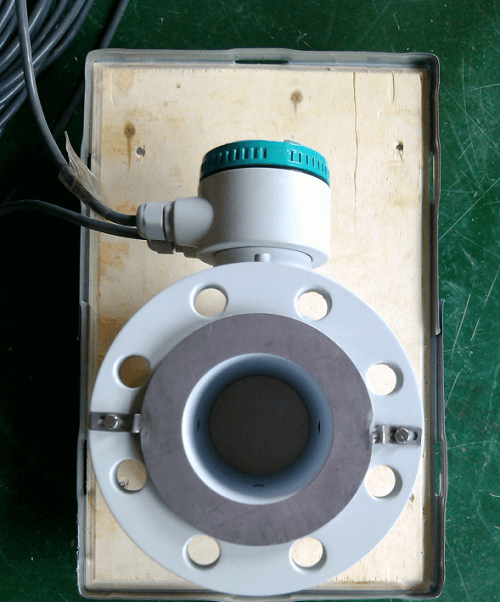

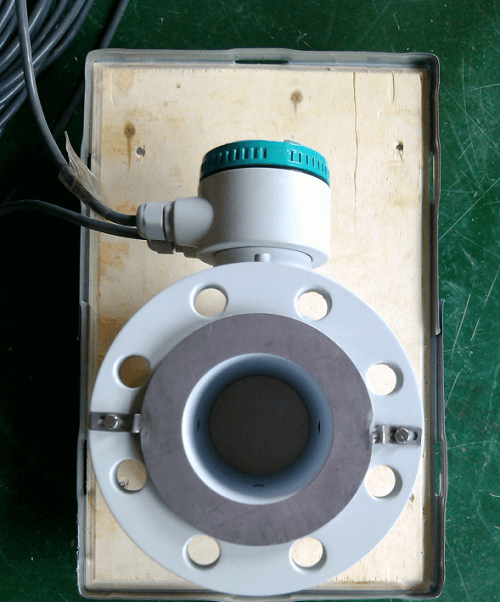

3. For pipeline material in steel, normal grounding could make flow meter working normally. For special pipeline material for example PVC material, electromagnetic flow meter must with grounding ring to make sure the well grounding and normal work of the flow meter.